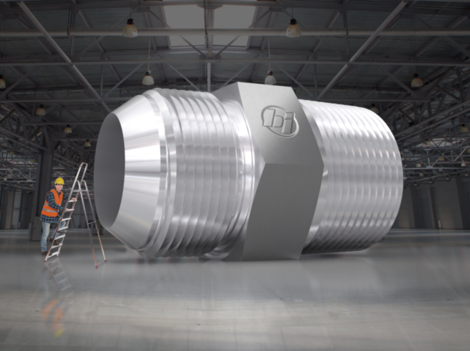

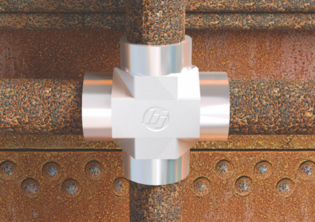

When your engineering team meets with ours, great things will happen. We have a dedicated staff that focuses on customized solutions for critical flow components. Whether it’s altering a standard or starting from scratch, you can count on the Brennan Engineered Solutions Team*.

Because we control the manufacturing process from end-to-end, we can offer the widest variety of sizes, materials, platings coatings, and customized solutions. Take advantage of our years of experience and keep projects on time by getting us involved early.