Click to jump to:

Hydraulic fittings help contain and direct the flow of hydraulic fluid in the conductor, prevent leaks and maintain pressure.

Learn the basics of hydraulic fittings to make the best selection for your system. Fitting designs continue to evolve to meet the latest safety and performance standards; so, it’s important to make sure you are meeting the strict demands of your application.

WATCH:

Connection Types

American Connections

NPT (National Pipe Tapered) style pipe threads have been widely used for over 100 years. NPT is a U.S. standard for tapered threads used on pipes and fittings. They are used to effectively seal pipes for fluid and gas transfer. The nominal pipe size can be identified by physically measuring the thread diameter, then subtracting 1/4″.

They are available in iron or brass for low-pressure applications and carbon steel and stainless steel for high-pressure.

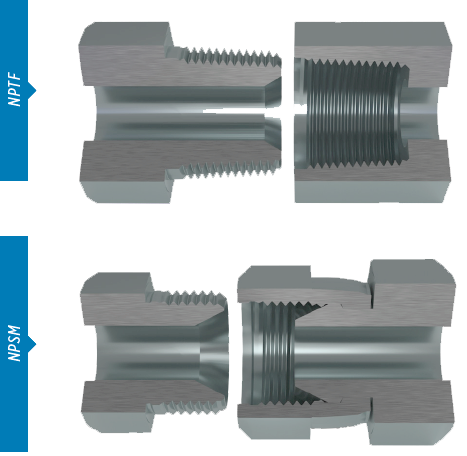

NPTF (National Pipe Tapered Fuel) style connections are widely used in fluid power systems. They have a tapered thread by which a seal is made by deformation of the threads. NPTF Threads are measured at the thread diameter and subtracting 1/4-inch to establish the nominal pipe size.

NPSM (National Pipe Straight Mechanical) connections are also often found in fluid power systems. The female component incorporates a straight thread with an inverted 30° seat. The male component has a straight thread and a 30° internal chamfer. A seal is made by compression of the 30° seat on the chamfer. This is considered a mechanical connection. If an NPTF male is properly chamfered it will also seal with an NPSM female connection.

Society of Automotive Engineers Thread (SAE)

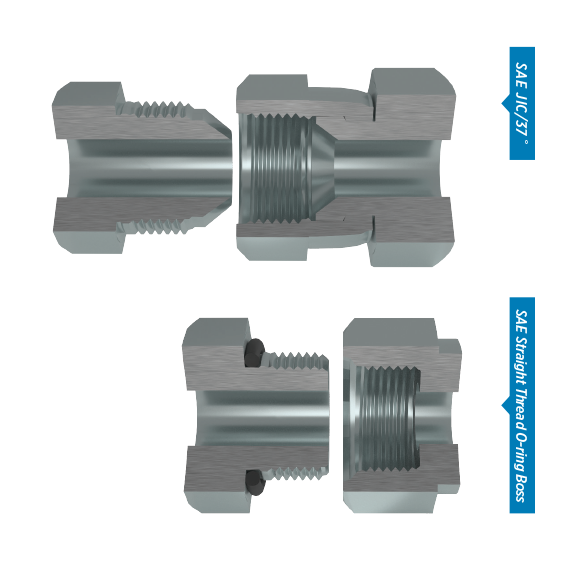

SAE J1926 Straight Thread O-Ring Boss (ORB) is recommended by the National Fire Protection Association (N.F.P.A.) for leak prevention in medium and high pressure hydraulic systems. The male connection is a straight thread with an O-ring. The female port has a straight thread and a machined surface to provide a smooth, flat surface (minimum spotface), along with a chamfer where the O-ring seats. It seals when the O-ring is compressed into the chamfer when mating the male connection. This is also considered a mechanical connection.

SAE J514 JIC/37° Hydraulic connections are common in most fluid power systems. Both male and female components have 37° seats. The seal is made by establishing contact between the male flared and female coned seat. This is also considered a mechanical connection.

SAE J512 45° connections are used in automotive, refrigeration and truck pipe systems. These connectors are typically brass material. The male and female connections have 45° seats, where the seal is make where the male flare and the female cone meet. This is a mechanical connection also.

NOTE dash sizes: -02, -03, -04, -05, -08, and -10 of SAE 37° and SAE 45° have the same threads, but NOT the same seat angles. Intermixing the two different types of fittings will result in leakage, so use care in measuring seat angles.

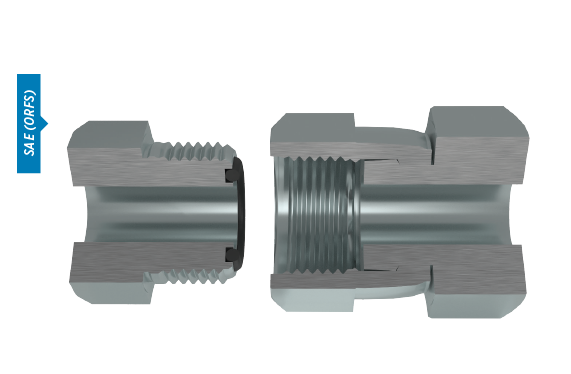

SAE J1453 (ORFS) O-ring Face Seal connections are considered the best for leak control. The male connector has a straight thread and an O-ring in the face. The female has a straight thread and a machined flat face. The seal takes place by compressing the O-ring onto the flat face of the female, similar to the split flange type fitting. The threads maintain the connection mechanically.

SAE J512 Inverted connections are typically used in automotive systems. The male connector is either a 45° flare within the tube fitting or a 42° seat in the machined adapter. The female incorporates a straight thread with a 42° inverted flare. The fittings are sealed at the flared surfaces. These threads also maintain a mechanical connection.

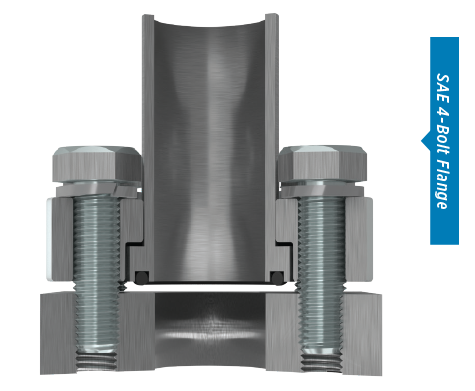

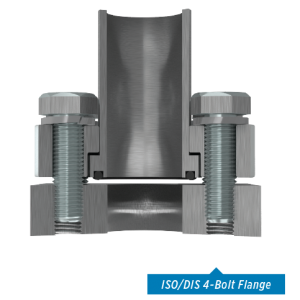

SAE J518 4-Bolt Flange* There are two pressure ratings for these connections: Code 61 which is considered the standard series and Code 62 which is the 6000 PSI series. The design is the same for each series, yet the flange head diameters and bolt hole spacing are larger for the 6000 PSI high pressure Code 62 connection. The female port of the fitting is a smooth, un-threaded port with four bolt holes set in a rectangular pattern around the port. The male is a flanged head with a groove for an O-ring and either split or captive flange halves and bolt holes which match the port. The seal is made where the O-ring is compressed between the flanged head and the flat surface of the port. The connection is held by threaded bolts.

*Excluding bolt sizes, SAE J518, JIS B 8363, ISO/DIS 6162 and DIN 20066 are interchangeable.

British Connections

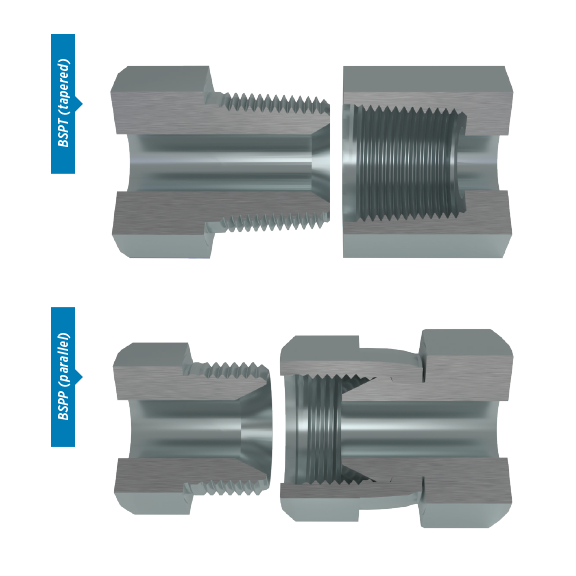

British Standard Pipe (BSP) and BSPT (tapered) connections are comparable to NPT, except most sizes have a different thread pitch, plus the OD’s and thread form are close, but not the same. Sealing takes place by distortion of the threads. Because of this, thread sealants are recommended when securing these connections.

BSPP (parallel) male connection is comparable to NPSM male except most sizes have a different thread pitch. A captive seal is made using metal to metal angled surfaces or a combination of metal to metal and an O-ring. This type of connection is very similar (but not interchangeable) with the American NPSM male. The female swivel BSPP has a tapered nose flareless swivel where the seal occurs on the cone seat of the male connector.

Note: the thread sizes are often expressed as fractional dimensions preceeded by the letters “G” or “R”, where “G” represents a parallel thread and “R” represents a tapered thread. Example: BSPT 5/8-14 can be designated by R 5/8 and BSP 1/16-28 can be designated by G 1/16.

German Connections

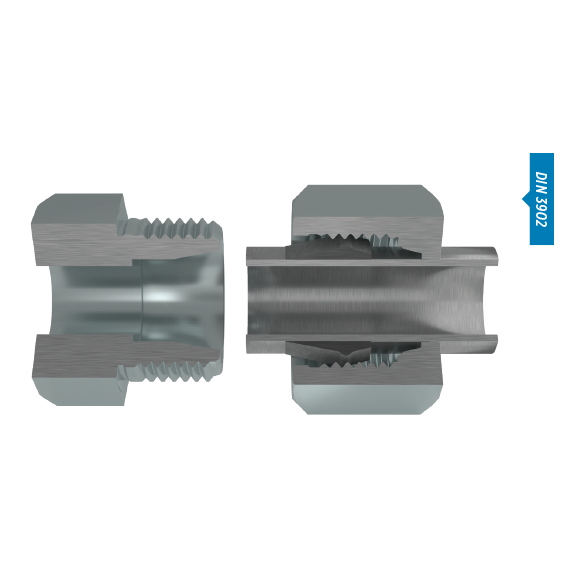

DIN 7631 Series is a common metric-style connection in hydraulic systems. The male connector has a straight metric thread with a 60° angle on the recessed cone. The female has a straight thread with a seat that is a tapered nose. The contact of the cone of the male and the tapered nose of the female flareless swivel is where the seal takes place.

DIN 2353/ISO 8434 series is a common male with three different possible female halves. The straight metric thread male has a 24° angle. Its recessed counter-bore matches the tube O.D. it is connected to. The female may be one of the following:

- A tube, nut and ferrule (compression style)

- A tapered nose flareless swivel

- A tapered nose flareless swivel with a DKO style O-ring in the nose

- Equipment Electrification in Mobile Hydraulics

- International Flanges: DIN 4-Bolt

- International Thread Types: DIN German Connections

- New DIN Cap & Plug Kits are Bigger and Stronger Than Ever

- What is a DIN Fitting?

- 4 Common Types of DIN Pneumatic and Hydraulic Fittings

- Using DIN Connections In Check/Non Return Valves

- Why More OEMs Are Using DIN Fittings

- New Strategic Partnership Means More Choices for DIN Fittings

Japanese Connections

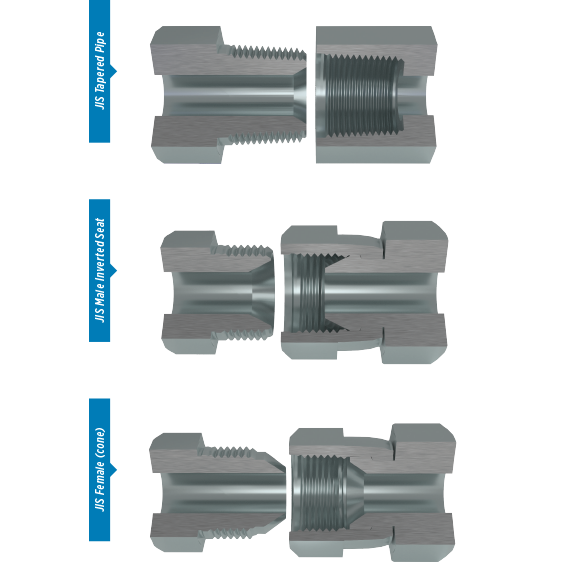

JIS Tapered Pipe (PT) has metric threads per JIS B 0203. These are JIS tapered threads and are comparable to the design of BSPT connections in their dimensions and appearance. JIS tapered thread connections are interchangeable with BSPT connections.

JIS 30° Male Inverted Seat connections are parallel pipe threads per JIS B 0202. JIS parallel connections are comparable to BSPP connections. JIS parallel thread connections are interchangeable with BSPP connections.

JIS 30° Female (Cone) Seat are parallel pipe threads per JIS B 0202. Japanese JIS 30° flare connections are comparable to American SAE 37° flare connections in application and sealing principals. Yet, JIS 30° flare angle and dimensions are different with threads that are similar to BSPP.

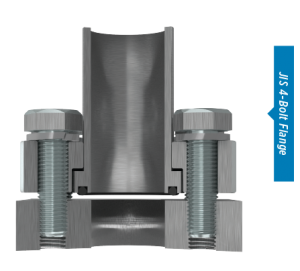

JIS B 8363 4-Bolt Flange connections are frequently used in fluid power systems. There are two pressure ratings for JIS B 8363 4-Bolt Flange fittings:

1) Type I Code 61 is the standard series 4-Bolt Flange

2) Type II Code 62 is the 6000 PSI series

Each design concept is the same, yet the flanged head diameters and bolt hole spacing are larger for the Type II 6000 PSI connection. Metric and inch bolts are each used with these connectors. The male connector has a flanged head with a groove for seating an O-ring and either a captive flange or split flange with bolt holes to correspond to the port. The female port of the fitting is a smooth, un-threaded port with four bolt holes set in a rectangular pattern in around the port. The seal is made where the O-ring is compressed between the flanged head and the flat surface of the port. The connection is held by threaded bolts.

JIS 210 Kgf/cm2 4-Bolt Square Flange incorporates a JIS 4-bolt square flange connection which is comparable to SAE 4-bolt flange connections with one difference – the flange itself is different and the JIS bolt pattern is square.

ISO Connections

ISO/DIS 6162 4-Bolt Flange is another common connection found in fluid power systems. There are two pressure ratings for this connection- Code 61: PN 35/350 bar which is considered the standard series and Code 62: PN 415 bar which is the high pressure series. They maintain the same design, yet with the bold hole spacings and flanged head diameters being larger on the PN 415 bar high pressure connection. Inch or metric bolts are found in these connections, however there is an “M” stamped on the port if metric bolts are to be used. The female port of the fitting is a smooth, un-threaded port with four bolt holes set in a rectangular pattern in around the port. The male is a flanged head with a groove for an O-ring to seat and either split or captive flange halves and bolt holes which match the port. The seal is made where the O-ring is compressed between the flanged head and the flat surface of the port. The connection is held by threaded bolts.

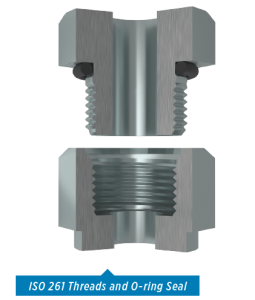

ISO 6149 Port and Stud Ends with ISO 261 Threads and O-ring Seal though it is similar to the SAE J514 Straight Thread O-ring Boss (ORB), this type of connection incorporates metric threads. The male connector has straight threads with an O-ring. The female port is also straight threads machined surface to provide a smooth, flat, accurately located surface (minimum spotface), along with a chamfer where the O-ring seats. It seals when the O-ring is compressed into the chamfer when mating the male connection. This is also considered a mechanical connection.

Instrumentation Fittings

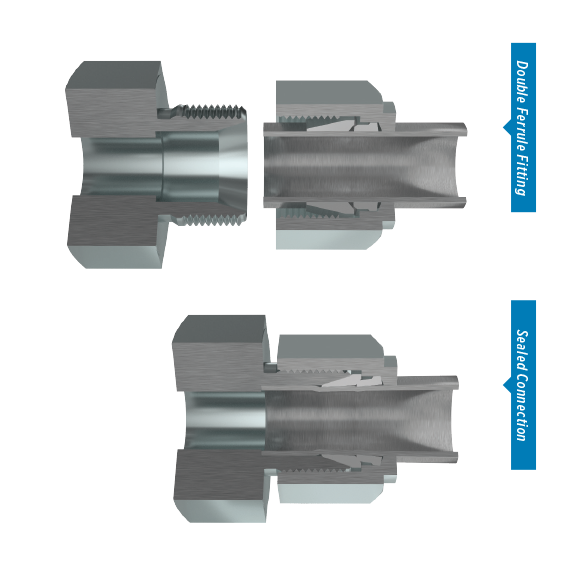

Double and Single Ferrule Instrumentation Fittings. Instrumentation fittings are widely used in fluid or gas transfer applications such as refineries, chemical plants and food processing plants. The male end of a double-ferrule instrumentation fitting has a recessed counter-bore which matches the tube OD being used, plus an inner cone. The seal is made between the front ferrule and the cone. The tubing is held in place by the swaging action caused by the tightening of the nut, which forces the front and back ferrules to bite into the tubing, firmly holding it in place. This allows for the use of un-flared tubing with these connectors.

The single-ferrule instrumentation fitting is similar, but has a larger front ferrule and no back ferrule. The sealing method is also similar. Both types of instrumentation fittings are commonly available in stainless steel and brass.

Instrumentation fittings have UNEF (extra fine) threads and sizing is determined by the outside diameter of the tubing being used.

- Why Measuring Temperature with RTDs is Important for Hydraulic Systems

- Key Materials Used in Pneumatic Hoses and Tubing

- Pipe Flanges: Types, Styles & Applications

- Hydraulics in Oil and Gas Operations

- Poly Alloy Vs. Brass PEX Fittings

- What You Need to Know About Applications for Stainless Steel Fittings

- Material Selection Mistakes Can Lead to Disaster

- Maintainable Hydraulic System Design: Redundant Systems

- Global Distribution of Hydraulic Fittings

- Four Primary Types of High to Low Pressure Tube Fittings

- Instrumentation Tubing: Welded vs Seamless

- What to Consider When Selecting Instrumentation Valves

- Flared vs Flareless Fittings in the Aerospace Industry

- Crucial Components to Aerospace & Defense Market Entry

- Designing Hydraulic Fittings and Flanges into a System

- Industrial Internet of Things in Hydraulics

- Drain Lines, Valves, Filters, Lines and Pumps in a Hydraulic System

- Advantages of Forged Steel Fittings Versus Other Processes

- Five Reasons to be Using Flange Fittings

- Flange Plugs: What are they?

- Air Brake Components in Trucks and Buses

- Why Use Push to Connect Fittings?

- Two Piece vs. One Piece Hose Fittings

- What is a D.O.T. Air Brake Fitting?

- Manifold Valves Video Overview

- Types of Push to Connect Fittings

- Checking In On Check Valves

- Reduce Costs with Proper Hydraulic System Maintenance

- A Comparison of Distribution Methods: Conventional vs Distributed

- The Role of Procurement in Fragmentation

- Markets and Applications for Instrumentation Valves & Fittings

- How the Instrumentation Market is Growing and What to Expect

- Instrumentation Valves for Power Generation Applications

Additional Resources

Thread Identification & Measurement Guide

This guide features 28 pages of helpful information and illustrations, tips for measuring & identifying common threads, visual ID and size guide for multiple fitting types, and thread dimension chart covering 15 different thread types.

Visual Thread Guide

This laminated Visual Thread Guide helps identify male pipe, SAE 37° Flare, SAE ORB thread sizes and SAE 37° swivel nut sizes.

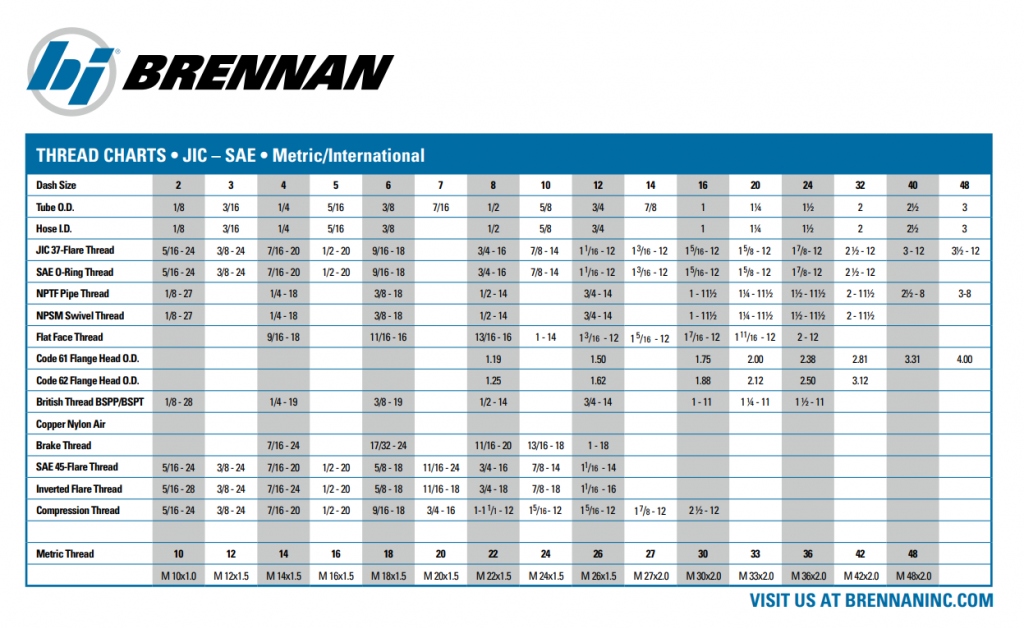

Thread Chart

Use this chart to match your measurements to the proper fitting size for your applications.