Connection Types: Flanges & Flange Fittings

What are Flange Fittings?

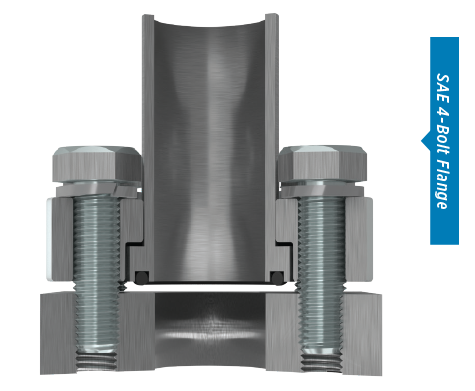

Flange connections are typically used in applications that will encounter exceptionally high pressures when using pipe or tubing with an OD over 7/8 inches. They may be bolted together to mate two sections of pipe (tube or hose), or bolted or screwed into the component to secure a flange fitting or section of pipe. Flanges can also be disassembled for easy access to modify the system, clean or inspect it. Certain flanges may also be permanently welded together or to the port section of the component like a motor housing or a valve port. More commonly, a flanged joint is made by bolting two flanges together with a gasket in-between to ensure a secure seal.

Advantages of Using Flange Fittings:

- Readily available

- Offer a large variety of sizes, shapes, combinations and materials

- Withstand high pressures

- Provide benefits to the piping system that traditional hydraulic fittings do not

- In large OD applications, they’re often able to be connected to pipe and component ports easily

- Good for ease of assembly in tight spanes

- Great in hard to reach areas where flexibility is required

- Reduce chance of components becoming loose in rigorous hydraulic applications

- The relevant temperature rating is limited by the O-ring seal material making them ineffective in high temperatures

- The weight can be problematic in systems where weight reduction is important

Two Primary Types of Flanges

SAE Code 61 Flanges are used for applications requiring working pressure of 3,000 to 5,000 PSI.

SAE Code 62 Flanges are used for applications requiring working pressure of up to 6,000 PSI.

Caterpillar 4-Bolt Flanges

There is also another style that must be accounted for and not interchanged with SAE Flanges. This other 4-bolt flange often found in the field is called a Caterpillar flange. This style is almost an exact match to the SAE Code 62 4-bolt flange. There is variance in thickness on the flange heads, and for this reason these connections should not be interchanged.

Not Interchangeable

Although many SAE 4-bolt hydraulic flanges might look alike or that different flanges and fittings might appear to be compatible, that is usually not the case. SAE Code 61, SAE Code 62 and Caterpillar 4-bolt flanges have dimensional variations and slight differences in configuration, plus the differences in allowable working pressure do not allow them to be used together or interchanged and care needs to be taken to properly identify the right connection to create a safe and leak resistant seal.