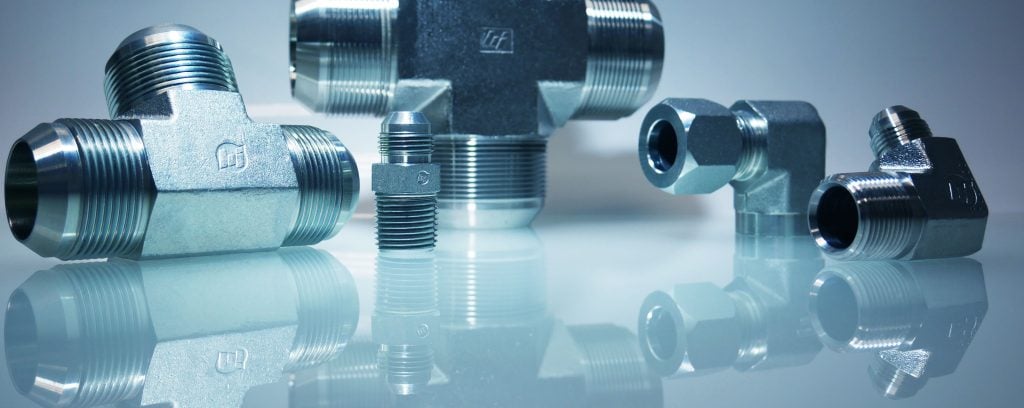

Connection Types: JIC (Joint Industry Council)

What are JIC Fittings?

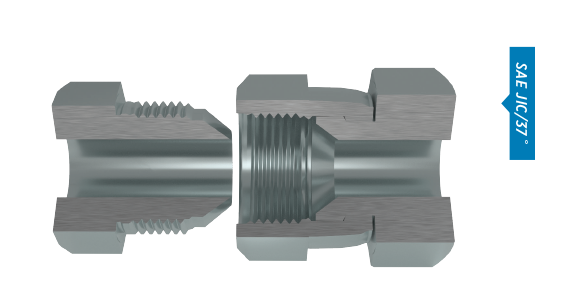

JIC (or Joint Industry Council) fittings, defined by SAE J514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel.

JIC Fitting hydraulic connections are common in most fluid power systems. Both male and female components have 37 degree seats. The seal is made by establishing contact between the male flared and the female coned seat. This is considered a mechanical connection. There are three components that make a tubing assembly; fitting, flare nut and sleeve.

Advantages of Using JIC Fittings:

- They are readily available

- Offer a large variety of sizes, shapes, combinations and materials

- Sizes are consistent with SAE fittings which makes them easily interchangeable and identifiable

- The absence of an O-ring makes them desirable in high temperature applications

- Can be disconnected and reconnected repeatedly without deformation (This is very useful in applications where equipment is frequently changed or swapped out. They are easy to maintain and install. Also, the combination of male a JIC fitting and female JIC swivel make orientation much easier.)

Disadvantages of Using JIC Fittings

- They have lower pressure rating than required in some instances (high virabtion applications)

- The metal-to-metal sealing design limits them to hydraulic, fluid, and non-critical applications

- Susceptible to flare damage and cracking due to over-tightening

Flared Fittings

Flared fittings provide significant design and performance characteristics as compared to pipe fittings and can be used with thin to medium wall tubing. In most hydraulic design applications, pipe fittings have long been replaced with flared fittings, particularly in military and aerospace equipment. In low to medium pressure applications, the most common connection type is a flared fitting. Single flare SAE 37° is the standard in most hydraulic systems. SAE standards for the maximum tube wall thickness must be followed before flaring the tube to match the fitting connection.

JIC fittings can easily be mistaken for SAE 45 degree flare fittings. Some sizes have identical threads and care should be taken to carefully measure any seat angles to differentiate.

Not to be Mistaken for AN (Army Navy) Fittings

JIC fittings are also commonly confused with AN (Army Navy) fittings. Although the two are dimensional identical, the AN military standard calls for tighter tolerances and defines all fitting types, where the JIC uses AN specifications as the base line for their own standards and covers fewer sizes. For these reasons JIC and AN fittings are not functionally interchangeable and so care needs to be taken to properly identify your connection to create a safe and leak resistant seal.