Connection Type: Double-Ferrule

Instrumentation Fittings

What are Double-Ferrule Instrumentation Fittings?

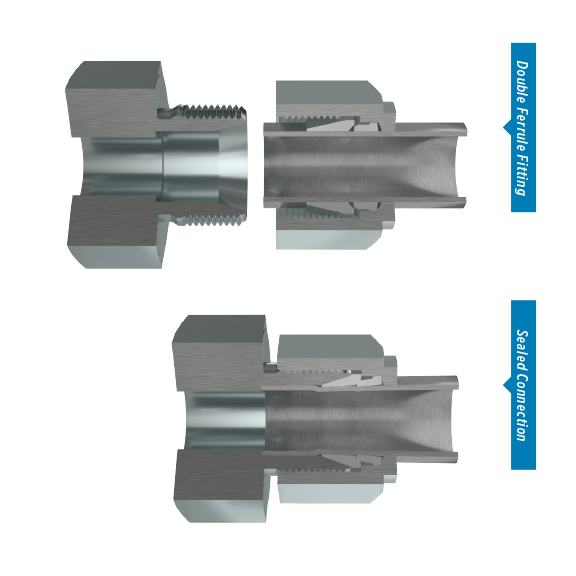

A double ferrule compression fitting is the most common instrumentation style fitting. They are regularly used in process measurement and control systems in aerospace, defense, chemical processing plants, medical equipment and oil & gas industries. Compression fittings are made up of three components: nut, body and ferrule (either single or double). This design creates a sequential grip on the tube. Instrumentation fittings have U.N.E.F. or (United National Extra Fine) threads and sizing is determined by the outside diameter of the tubing being used. The ferrule coins and compresses into the tube to provide a tight grip on the tube surface.

The male end of a double-ferrule instrumentation fitting has a recessed counter-bore which matches the tube O.D. being used, plus an inner cone. The seal is made between the front ferrule and the cone. The tubing is held in place by the swaging action caused by the tightening of the nut, which forces the front and back ferrules to bite into the tubing, firmly holding it in place. This allows for the use of un-flared tubing with these connectors.

Disadvantages of using Double Ferrule Instrumentation Fittings:

- Compared to other tube fittings, they have a more complex design that could lead to improper installation

- The selection of the wrong tubing is a very common mistake in installation. Proper selection, handling and installation of tubing are essential for reliable tubing system performance

- In some cases, lubrication is required on the threads of the mating nut to prevent galling

- The tubing needs to be carefully cut, deburred, chamfered and free of defects or scratches, before installation

- The application and materials used in the manufacture of the fittings, make corrosion a consideration during system design

- They are more expensive than non-instrumentation style fittings

Advantages of using Double-Ferrule Instrumentation Fittings:

- They are readily available and offer a large variety of sizes, shapes, combinations and materials

- Double ferrule compression fittings make a strong and leak-safe seal when installation steps are properly followed

- They have greater vibration resistance then other instrumentation fittings like Cone and Thread fittings

- They are extremely reliable and safe in systems with low to high pressure ratings

- They perform equally well on thick and thinner walled tubing

- Because of their flexibility, reliability and relative ease of installation, double-ferrule compression fittings are a standard choice in overall instrumentation system design

There are other instrumentation and compression style fittings. One example, the single-ferrule instrumentation fitting, is similar to the double-ferrule, but has a larger front ferrule and no back ferrule. There are many varieties of compression style fittings and many different applications in which they are used. For these reasons care needs to be taken to properly identify the right connection to create a safe and leak resistant seal.