Connection Types: ORFS (O-ring Face Seal)

What are ORFS fittings?

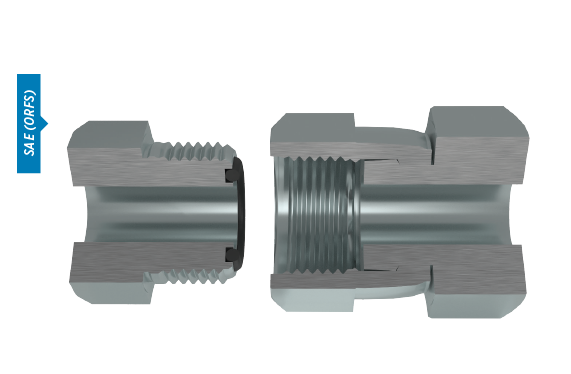

As the name implies, ORFS, or (O-ring Face Seal) fittings incorporate an O-ring at the face of the fitting. Made to SAE J1453 standard, ORFS connections are commonly manufactured in carbon, nickel plated carbon & Stainless steel and typically use Buna-N or Viton, 90 Durometer O-rings that seat into a groove in the face of the fitting. This is known as an elastomeric seal.

The seal is created when the o-ring compresses between the o-ring face of the fitting and flat face of the mating ORFS fitting or the formed tube. When the connection is tightened the O-ring compresses against a flat face of mating fitting or tube.

Disadvantage of using ORFS fittings:

- The relevant temperature rating is limited by the o-ring seal material making these fittings ineffective in high temperature applications.

- They’re readily available and offer a large variety of sizes shapes, combinations and materials

- Can eliminate leaks in hydraulic systems with high operating pressures

- These elastomeric seals provide a leak-proof, drop-in replacement for SAE 37° flared tube fittings, literally eliminating hydraulic leaks when used properly

- Used in the majority of applications where there are high pressures that are subject to flexing or pressure surges and they are also the preferred connection in high vibration systems because the soft O-ring seal absorbs shock better than any metal-to-metal sealed fittings

- Can be easily connected to a range of tubing grades by silver brazing or forming

- The nature of ORFS fittings resists complications associated with over-assembly as they can be over torqued by as much as 200%

- The flat face connection design coupled with the replaceability of the o-ring, makes these fittings reusable and easily maintainable in the field

There are other fittings that make connections using an elastomeric seal. For example; Metric fittings, ISO 9974, incorporate an elastomeric seal in a groove recessed into the fitting body. The male ORB or (O-ring Boss) fittings uses an o-ring that seats in a chamfer in the mating female port. Flange connections also use an o-ring in a flat sealing face. The main difference being that a flanged joint is made by using bolts to connect the two flanges together with a gasket in-between to ensure a secure seal. While, the ORFS fitting is the threaded connection.

O-ring face seal fittings are often the best or sometimes only practical choice and care needs to be taken to properly identify the right connection to create a safe and leak resistant seal.