Hydraulic system maintenance is critical to the service life of equipment and the safety of personnel. It is imperative that maintenance technicians comply with necessary safety precautions. They must have the necessary training and continuing education on the specific equipment and know how to properly take samples, use the right test equipment and record data that can be used for ongoing preventative and corrective maintenance.

Anyone who works around hydraulic systems that carry hot oil under high pressure needs to be cautious and aware of the powerful capabilities of

today’s equipment.

Hydraulic systems in stationary industrial equipment and mobile construction equipment can operate at temperatures in excess of 200° F and pressures ranging from 2,000 to 10,000 PSI. Severe injury of burned skin or eyes have occurred due to fluid sprays from cracking a fitting, old and brittle hose that burst, or systems that were not properly depressurized before maintenance. Most often when this occurs it is during maintenance where proper processes were not followed. Even at low temperatures where it would not burn, additives in the fluid can cause severe skin irritation, or the high pressure can penetrate the skin. Improperly secured system components under high pressure have been known to burst away from their connection, sending hose and fitting flailing at the speed of a bullet. There have been cases reported where workers in the proximity have literally been beaten to death. In addition, injuries also occur because of improper repairs or the lack of adequate preventative maintenance (PM) procedures.

Hydraulic system maintenance is the most important activity in service equipment. Unfortunately, maintenance mechanics are not a primary consideration for the design engineer when developing a hydraulic system, so maintenance personnel must be specialists in their own right. There are two primary functions of proper hydraulic system maintenance; Preventive Maintenance and Corrective Maintenance.

Simply put; we change the oil in our cars on a scheduled basis to prevent the engine from seizing up. If in the process we discover a leaky gasket, we replace it as corrective maintenance so….the engine doesn’t seize up. When I was 19 I bought a car from my step- brother. It had 30,000 miles on it. I trusted he’d taken care of it, even though he was not very mechanically inclined. But I took for granted he knew the basics. While driving a couple hundred miles on a short trip that first weekend I had the car, the engine suddenly seized up, the gasket blew and oil sprayed the windshield…at 65 miles per hour on a hilly road. I came to a stop less than a foot from the edge of a cliff. He had never changed the oil. He didn’t know he was supposed to. True story. Ignorance is not bliss.

The Four Considerations

1.

Preventative Maintenance

Preventative maintenance (PM) of a hydraulic system is a crucial function to maintaining the service life of equipment, reducing costs associated with unplanned equipment shutdown and the safety of personnel.

One the most important considerations in a PM plan is addressing stored hydraulic energy, such as a pressurized hydraulic reservoir. Pressure must be released from the reservoir before replacing a fitting, hose or any other maintenance procedure. Otherwise there can be a high likelihood of the violent release of hydraulic energy which can cause serious equipment damage or bodily injury. To avoid this, precautions must be taken to safely release the pressure prior to disassembling any part of the system.

A hydraulic PM plan should follow the equipment and filter manufacturer’s recommended maintenance schedule, take into consideration the working environment and use test points to draw samples from the line for fluid testing and analysis to ensure the system is free of contamination. Regular standards and procedures should be documented and adhered to for the proper maintenance of any hydraulic system.

Hydraulic system PM procedures are straightforward when followed properly and on a regular schedule. A preventive maintenance schedule of a hydraulic system is based on known or suspected failure modes. This includes inspection and replacement of old hose, ensuring connections are properly matched and meet specification, plus checking for contamination that can clog the system particularly in an in-line valve.

Like changing the oil in your car, preventive maintenance is a regularly scheduled procedure that maintenance techs must follow. And because maintenance of hydraulic equipment is so critical, effective procedures must be documented for each task. Because maintaining different types of systems may require different procedures, the specific equipment’s PM plan must be closely adhered to and include a minimum of:

- Step by step instructions

- Any possible hazards inherent to the specific type of equipment

- Environmental concerns

- Safety precautions for each step

- Specific tools or equipment required for the maintenance of the specific equipment

- Traceable parts for performing the procedure(s)

2.

Corrective Maintenance

System components should be inspected during preventative maintenance to address any anticipated issue before failure occurs. Ideally the need for corrective maintenance can be identified and addressed during PM or in preparation for a scheduled or planned shutdown. Be sure any repair of components is performed properly. If not, issues may arise that can cause even greater harm.

If a component needs to be replaced before its anticipated life cycle, the reason should be documented in the PM plan and corrective measures put in place to eliminate having the issue occur in the future. The lack of proactive corrective maintenance can cause easily avoidable hydraulic component failure.

SAFETY FIRST: Following proper procedures during system maintenance is critical

If a technician is not aware of the stored energy in a line and cracks open a fitting or over tightens it, the fitting can blow off or crack, releasing fluid into the atmosphere. The same can happen if a pressurized hydraulic reservoir tank is not handled according the manufacturer’s maintenance requirements. The first step in ensuring safe maintenance protocols is to isolate the system to protect the technician from hazardous energy sources. Stored hydraulic energy can be isolated with lockable or monitored isolation valves.

As with any fluid, especially when under pressure, it is typically very challenging to isolate hydraulic energy because it will follow any existing leak path. In the simplest

of cases, most of us know what it’s like to do a poor job patching a leaky roof. You’ll always be chasing the leak. Yet in hydraulic systems, adherence to lockout procedures and being aware of the difficulties in controlling hydraulic pressure and isolating energy is imperative for safe machine operation and maintenance.

In the design phase, machine manufacturers integrate lockout devices to verify, control and isolate energy in the hydraulic system. Over the past decade, laws, legislation and OSHA standards have imposed regulations upon manufactures relating to hydraulic maintenance in order to ensure they are conforming to safety regulations in the design and manufacture of equipment.

3.

Lockout & Tagout Safety Procedures

LOTO, or lockout and tagout, is the most relied upon procedure for maintenance safety. According to OSHA, “Lockout/ tagout refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities. This requires, in part, that a designated individual turns off and disconnects the machinery or equipment from its energy source(s) before performing service or maintenance and that the authorized employee(s) either lock or tag the energy-isolating device(s) to prevent the release of hazardous energy and take steps to verify that the energy has been isolated effectively”

Lockout devices isolate energy in a safe “off” position during maintenance. They have positive restraints that prevent equipment from becoming energized without a special key.

Tagout devices are warnings that an authorized employee fastens to energy-isolating devices to warn employees not to re-energize the equipment while it is being worked on.

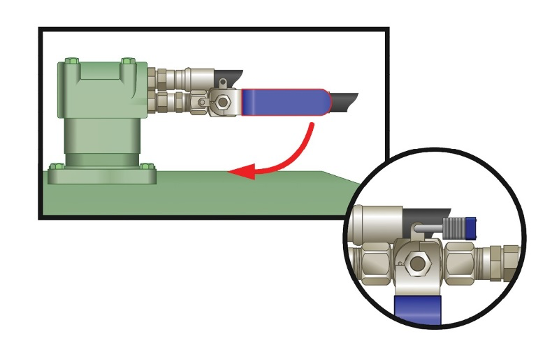

Demonstration of how to lock out a ball valve. Image courtesy of CD Industrial Group

Photo: mobilehydraulictips.com

It can be very hazardous to crack or loosen a connector on an accumulator port that retains stored energy in order to release pressure. This will most likely cause highly pressurized fluid to release at a speed that can cause injury. Another relatively common mistake is to bleed a system by slowly loosening a split-flange connector. If the system is under pres- sure and the four bolts are loosened the O-ring seal will burst releasing the stored energy of the pressurized fluid, which can cause very serious bodily harm.

Prior to system inspection or maintenance be sure to properly depressurize the system according the manufacturer’s procedures. This minimizes the risk of hydraulic fluid bursting from a machine. Simply turning the system or machine off does not lower the pressure in a cylinder or accumulator.

When performing maintenance, never reuse old hoses or fittings. Especially do not reuse O-rings. If a flange fitting or O-ring boss is being disassembled and the fitting is still in good shape, it is still necessary to replace the O-ring. An O-ring that has been through multiple cycles of pressure and then exposed to the atmosphere during maintenance can become dry, brittle and will likely crack. If it is reused the opportunity for system failure or the potential of a burst fitting is very high.

4.

Proper Component Selection

Ensuring a leak-free hydraulic system begins with the design, which involves selection of the correct hydraulic fittings, hoses and other components for the application. This could be a hose-end connection, hose or tube to port, a tube end or flange fitting. If it is a port connection, or 4-bolt flange, the correct O-ring material must be selected, which typically depends on the media the system is carrying, its temperature and pressure. The type of media and external atmosphere is also going to dictate fitting (and hose or tube) material.

Considerations for Choosing the Proper Hydraulic Fitting

Application Dictates Material: System application and environment dictates the selection of fittings. Common heavy equipment and industrial applications call for carbon steel, usually with a zinc electroplated coating for corrosion resistance. If the application has the potential for high corrosion, stainless steel or even brass can be the best selection.

Media: The system fluid and external atmosphere that comes into contact with the fitting is of primary consideration when selecting the fitting material, along with tube or hose material.

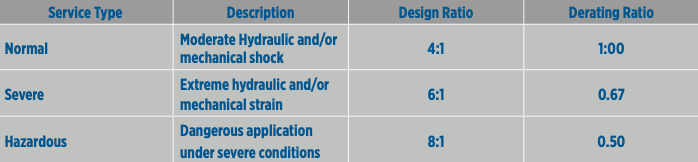

Pressure: Hydraulic system design is dictated by many factors, including the rated working pressure of the system. The working pressure for minimum burst depends on fitting selection based on a 4:1 design ratio under operating conditions that undergo moderate mechanical and hydraulic shocks. This ratio is based on the material in relation to the connection’s dynamic pressure rating, where the fitting pressure rating is equal to or higher than the pressure of the system. A derating factor is the operation of a device at less than its rated maximum capability in order to prolong system service life.

During system construction or maintenance ensure the pressure ratings of the new or replacement components are compatible with the system. During maintenance do not use whatever is lying around, instead be sure to follow the OEM requirements for the equipment.

The table below shows service, design and derating factors based on severity of the application:

Reliability: The reliability of a fitting is only as good as following proper selection criteria, and correct installation and maintenance. It is not uncommon for an NPT fitting to be over tightened when trying to correct a leak. This typically leads to the fitting becoming cracked or the threads being striped, which can then leak causing damage to equipment and personnel. In addition, when over torquing a JIC fitting the flares can crack and ultimately leak. Often, where the applications are suitable, the most reliable connection is an O-ring face seal fitting or a DIN metric fitting with an elastomeric seal. These fittings can reduce the chance of over- torque and minimize the chance of leaks.

Size: The fitting size is based on the hose or fitting OD and wall thickness, which itself is based on system flow rate, pressure, media and external environment. The wall thickness is dependent on these conditions and the fitting style. For instance a flare fitting may have a limitation to maximum tube wall thickness, where a 24° flareless bite type fitting imposes a limitation on the minimum wall thickness.

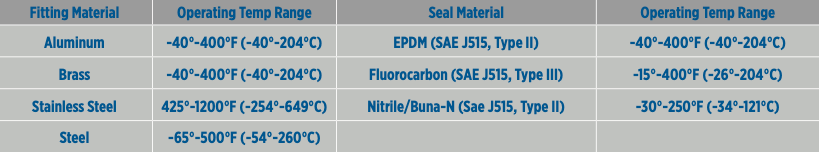

Temperature: As with any other condition of the application, the temperature of the system environment drives the fitting temperature rating. What a fitting can withstand is dependent on the type of material (material plating where applicable) and if there is an O-ring seal. If an O-ring seal is required under very high temperatures a metal to metal O-ring face seal type fitting may be the best selection. The table below shows temperature ratings for various fitting and seal materials:

Improper Couplings

Mismatched fittings can cause a dangerous rupture to a hose, tube, component assembly or entire system. This is particularly dangerous if a low pressure fitting or other component is connected to a high pressure system.

Hydraulic fittings must also be corrosion resistant and strong enough to withstand the high pressures experienced in a hydraulic system. It is also imperative that the fitting material be compatible with the tube or hose and the media the system is carrying and atmosphere outside the system. Depending on the grade or alloy, steel fittings are typically rated to 18,000 PSI and are commonly used in agricultural, construction and industrial equipment due to the high pressure requirements and necessary fitting strength.

However, in applications from food processing to off-shore oil & gas drilling, fittings and other components are most often stainless steel or other exotic alloy. In conditions such as off-shore rigs the fittings and lines not only carry corrosive media, but the outside atmosphere of salt water or spray can cause corrosion or pitting. If a common steel fitting is used in this type of application, there is a significant chance for failure that can not only cause damage to the system and be hazardous to workers, but can be very costly out on an oil platform or deep undersea.

Conclusion

The service life of equipment and safety of operator personnel make hydraulic system maintenance an absolute must in any application. A maintenance mechanics remains an after thought in the design process of a hydraulic system. This requires that maintenance personnel have a high IQ regarding hydraulic system maintenance and considerations can be made to increase system safety, maintain system performance and ensure system stability.

Performing preventative maintenance will reduce costs associated with unplanned equipment shutdown and ensure the safety of personnel. During preventative maintenance routines, the system components should be inspected to address potential issues prior to system failure. Corrective maintenance should be performed when an issue is discovered with a component in a hydraulic system. Using a lockout device will isolate system energy in a safe position during maintenance and will provide safety to maintenance personnel. A tagout device will provide warning to authorized personnel that the system is undergoing maintenance and should not be re-energized. Finally, selecting the proper components for hydraulic connections will ensure a leak-free system. These considerations will consistently provide safe and effective hydraulic system maintenance to ensure reduced costs while increasing personnel safety.