DIN stands for “Deutsches Institut für Normung”, meaning “German institute for Standardization”. DIN 2353 tube fittings are most commonly used in industrial, oil & gas and construction equipment

in hydraulic and pneumatic applications. Metric O.D. sizes range from 4mm to 42mm with the most common industrial applications using carbon steel or stainless steel material. There are three series of tube port end connections: tube-to-tube, tube-to-female port and tube-to-male thread.

DIN Metric and BSPP (British Standard Parallel Pipe) are the most common thread styles in Europe. DIN type tube fittings conform to the requirements of ISO 8434-1, DIN 2353, and DIN EN 3850 standards. This ensures the interchangeability with leading brands of fittings.

As with other compression style fittings, DIN 2353 fittings consist of a body, cutting ring (ferrule) and nut. DIN connections are used in:

TUBE FITTINGS

ALTERNATING VALVES

BANJO AND SWIVEL COUPLINGS

CHECK VALVES/NON RETURN VALVES

The availability of a variety of body styles and threaded connections allow DIN 2353 fittings to meet many connection challenges. These flareless bite type metric fittings are the most widely used bite type fittings in the world. As with other compression style fittings, DIN fittings consist of a body, cutting ring (ferrule) and nut. On assembly, the two cutting edges of the ring (ferrule) bite into the outer surface of the tube ensuring the necessary holding power and seal for high operating pressures and extreme vibration.

MATERIAL

For the best results, metric DIN 2353 fittings should be made with high quality materials. Stainless steel 1.4571 (316Ti) is the gold standard, providing exceptional temperature and corrosion resistance. Stainless steel 316Ti is used in environments with high salt levels, acidity, or near weld seams. Because of the long service life of this material there is a significant reduction in total cost of ownership, which leads to few parts replacement and lower maintenance costs.

Stainless steel 1.4571 (316Ti) DIN 2353 fittings withstand harsh environments with the presence of:

ACID

DIRT

HIGH HEAT

AND OTHER CORROSIVE SUBSTANCES IN THE AIR

PHYSICAL IMPACTS

SALT

VIBRATIONS

High quality DIN 2353 Metric Bite-Type Fittings and Adapters should be made of 1.4571 (316Ti) V4A materials for most applications that require extreme temperature and corrosion resistance. However, many applications are well suited for carbon steel which can provide exceptional corrosion protection when applying a specific zinc-nickel plating that far exceeds U.S. and international corrosion resistance standards, including VDMA 24576 class K5. Zinc-nickel plated fittings should not experience any traces of white or red rust even after 1000 hours of exposure to salt spray testing and provide:

GOOD PAINTABILITY

HIGH ABRASION PROTECTION

HIGH TEMPERATURE STABILITY

LOW CORROSION WHEN EXPERIENCING CONTACT WITH ALUMINUM OR STAINLESS STEELS

APPLICATIONS AND INDUSTRIES:

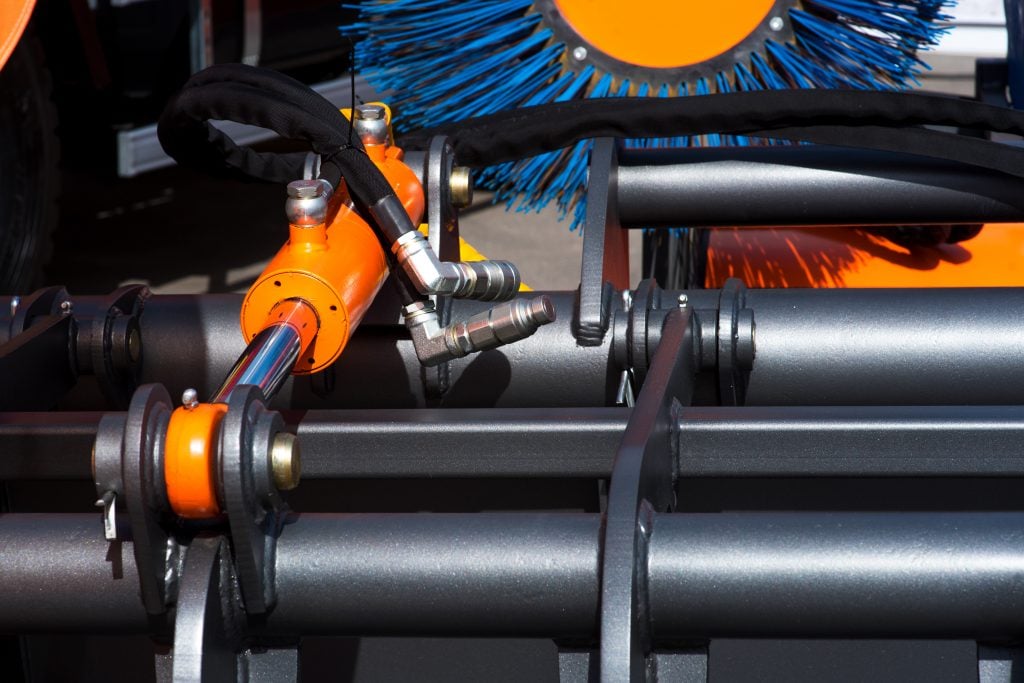

DIN 2353 Metric Bite-Type Fittings are commonly used in industries where tough environmental conditions

are prevalent:

CONSTRUCTION EQUIPMENT

DRILLING PLATFORMS

HYDROPOWER PLANTS

MACHINE TOOLS

RAILWAY TECHNOLOGY

RECYCLING EQUIPMENT

SHIPBUILDING

WIND TURBINES

MOBILE & STATIONARY HYDRAULIC EQUIPMENT

MINING

POPULARITY AMONG U.S. OEMS

With their growing popularity globally, many U.S. OEMs are adopting DIN fittings. This, combined with the rise in equipment being imported into the Americas from European manufacturers, is resulting in DIN metric fittings becoming more common in the U.S.

For decades JIC fittings have been the industry standard in the U.S. However, they are more susceptible to cracked flares from over torqueing. The mated sealing surfaces in DIN metric fittings

and O-ring face seal fittings reduce the risk of over torqueing and provide greater reliability because of the elastomeric seal in the mating surface.

As equipment design is requiring higher pressure ratings OEMs are choosing DIN metric fittings more frequently. Though JIC and NPT fittings are commonly used in many applicable applications, in many cases they are not rated for higher pressures requirements designed into equipment today, especially coupled with high vibration. Instead, more and more applications require specially-rated metric DIN connections.

DIN 2353 24° CONE

Both male and female of a metric DIN 2353 24° cone fitting have straight metric threads. The tube OD is mated with a 24° seat recessed counter bore of the male fitting. The female mating component can be:

A METRIC DIN 2353 FEMALE TUBE FITTING

METRIC TUBE WITH A CUTTING RING AND NUT

24-DEGREE CONE WITH AN O-RING EITHER WELDED OR END FORMED ON METRIC TUBE

The seat angle should be measured from the fitting centerline using a 12° gauge. The sealing of the two components is between the 24° seat in the male end and the corresponding female end.

DIN 2353 PRESSURE SERIES

It is important to note that DIN 2353 fittings are offered in 3 different pressure series – LL for Extra Light used in low pressure applications, L for Light used medium pressure applications and S for Heavy used high pressure applications. They are identified by measuring the thread size and pitch as well as tube OD.

METRIC STANDPIPE FITTINGS

A Metric Standpipe fitting is made of three preassembled pieces:

1. BITE SLEEVE

2. NUT

3. STANDPIPE

Adjustable standpipe fittings facilitate the connection of a metric tube with a 24° conical bore. Tightening the nut onto a DIN 2353 male connection, compresses the bite sleeve onto the tube of the standpipe, which makes the seal.

BANJO FITTINGS

Metric and BSPP (British Standard Parallel Pipe) Banjo fittings have two components; a perforated hollow bolt and spherical union for fluid transfer. They are primarily used in medium to high pressure applications (up to 800 bar/11,600 psi).

The main benefit of a banjo fitting is they do not have to rotate relative to the fitting connection so the hose does not twist when screwing the fitting into place. It also allows the pipe exit direction to be adjusted relative to the fitting, allowing the bolt to be tightened independently.

Banjo fittings are used in many applications, especially in the automotive and mobile equipment markets, such as:

BRAKE CALIPER CONNECTORS

FUEL DOSING FOR SCR (SELECTIVE

CATALYTIC REDUCTION) SYSTEMS

FUEL FILTER CONNECTORS

HYDRAULIC CLUTCH SYSTEMS

POWER STEERING FUEL LINES

TURBO CHARGER OIL FEED LINES

VARIABLE VALVE TIMING SYSTEMS

CHECK/NON RETURN VALVES

A check valve, otherwise known as a non return valve is a spring loaded valve used in liquid systems where the flow should only go in one direction and safeguards from back flow. These valves are able to be installed inline and look very much like a large fitting.

Check valves are flow sensitive and rely on the inline fluid

or gas pressure to open and close. An internal disc, regulated by a spring, allows flow to pass in one direction. If the flow decreases or is forced in the opposite direction, the spring begins to close the disc to stop the back flow. Non return check valves are typically made of just a few components such as a body, seat, disc and spring. Since the flow can only go in one direction, the outer body should have an arrow pointing in the direction of flow so it is not installed in the wrong direction. Depending on the application, some designs may also incorporate a hinge pin, stem, ball, disc arm, elastomers.

Metal sealing surfaces will typically allow some leakage. Therefore, where zero leakage is required, especially when gas or certain hazardous chemicals are being transferred, elastomers such as Buna-N or Viton (FKM) should be used to provide a leak-tight shutoff.

Some of the most common metric and BSPP threaded check valve tube connections are available in:

A. 24° FLARELESS TO 24° FLARELESS

B. 24° FLARELESS TO BSPP OR METRIC PARALLEL – ELASTOMER SEAL

C. FEMALE BSPP TO FEMALE BSPP

ALTERNATING VALVES

European style alternating valves are T-shaped and allow the flow to pass from one of two inlets, which then passes through an outlet port. An internal floating ball bearing shuts the inlet port that is not in use. This shutting off of the opposite inlet port occurs when the floating ball bearing is moved by the pressure coming from the inlet flow. When pressure is

to flow from the reverse direction, the alternate port is shut off– allowing the flow to come from the opposite source in the system, then to the outlet port.

The ball in an alternating valve provides metal-to-metal contact with a resilient seal seat to ensure

a leak-tight shutoff of liquid or gas. However, they should not to be used with weld nipples, swivel nuts or any connection that does not allow contact with a shoulder stop in the inner cone. Typical end connections are 240 flareless shuttle valve tube style.

Alternating valve bodies are normally made with carbon steel with a steel ball.

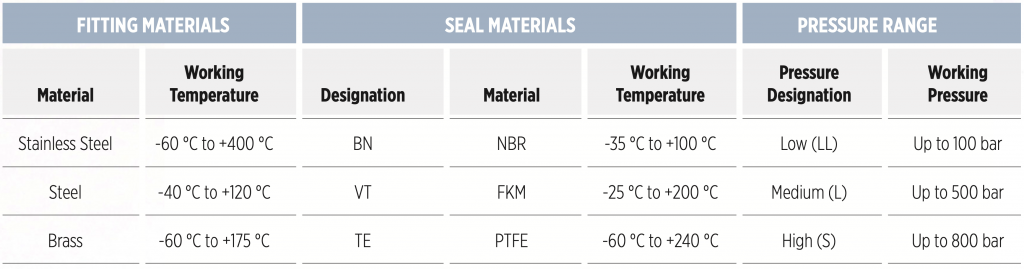

REFERENCE TABLE FOR DIN 2353 CONNECTIONS

ALLOWABLE WORKING TEMPERATURE AND PRESSURE RANGE FOR DIN TYPE TUBE FITTINGS WHICH MEET:

ISO 8434-1, DIN 2353 AND DIN EN 3850