For the safety of our roadways, air brakes are the most important component of commercial motor vehicles. The braking system on semi-trucks, large straight trucks, garbage trucks and school buses use compressed air to push the brake shoe lining onto the brake drum creating friction to slow the vehicle. That may not seem very complicated, but it is. The system to slow down a vehicle that may weigh 80,000 pounds fully loaded is not only complicated, it’s critical. Air brakes have to work effectively every time and they must be adequately maintained.

In 1980, a 40 foot straight truck moving van with a deck over the cab was on route to

the customer’s house for unloading outside of Syracuse, New York. The truck had

an 11,500 pound tare weight and was carrying 20,000 pounds of furniture (that’s a total weight of 31,500 pounds). Coming off the highway down a steep ramp the driver was frantically pumping the brakes. There was a tee at the bottom of the ramp with the option to only turn right or left. Straight ahead was a 5 foot tall earthen embankment, over that was a 20 foot drop to railroad tracks, and past that was another drop to a river.

Continually picking up speed and only seeing the embankment ahead, the driver cranked the steering wheel for a right-hand turn. The passenger side was completely up off its wheels, the 40 foot truck seemly flew through to the right, laid over on its side smashing onto the road facing the direction of the right turn as the top of the truck slammed into the earthen embankment, lying on its side in the road. Facing the correct direction, but not on its wheels. Going straight would surely have crushed the cab into the embankment, killing the driver and passenger; then would have flipped over and tumbled down to the railroad tracks and possibly tossed and turned all the way to the river below.

Fortunately the driver and passenger were not seriously injured, yet all of the furniture was destroyed. The moral of the story . . . the air breaks had not been properly maintained.

In 2009, a long awaited mandate from The National Highway Traffic Safety Administration (NHTSA) issued new braking standards for commercial trucks, requiring that a tractor-trailer traveling at 60 miles per hour must come to a complete stop in 250 feet- a dramatic, but necessary, change from the previous standard of 355 feet. This reduced a truck’s required stopping distance by 30%. Had that standard on maintenance of air brakes been in place in 1980, the furniture truck would likely not have crashed.

Why Air Brakes are Used on Commercial Vehicles

As the name implies, air brakes rely on air since there is virtually an unlimited supply in the atmosphere. Therefore, unlike hydraulic brakes that rely on fluid that can be depleted or leak, if properly maintained, air brake systems will never be depleted.

Excluding the engine, air brake assemblies are one of the most complex systems found on any type of commercial vehicle. They are used on tractor-trailers, many larger straight trucks, school buses, fire trucks and even trains. Air brakes are the best method for safely stopping heavy vehicles, and they are more complex than hydraulic brake systems used on lighter vehicles. Since people interact with vehicles that use air brakes, from mechanics to drivers, it is extremely important to understand how they function and their potential limitations.

Air brakes were initially invented for trains by George Westinghouse in the late 1800’s. When proved to be successful in railroad applications, truck manufacturers began incorporating them. They are safer and more reliable than hydraulic brake systems on commercial vehicles due to:

• The air supply being unlimited, insuring the active supply of air it relies on from being depleted.

• Compressed air is stored in tanks, yet if the compressor fails, the brakes can still bring the vehicle to a stop. This happens because there is enough air in the system that if the compressor is dislodged from side of the motor or the whole system shuts down, the brakes can still stop the vehicle.

• If there is a significant air leak in the system there is fail-safe spring brake which will activate and bring the vehicle to a stop. That’s one reason why it is important to properly maintain they system.

With a hydraulic brake system, if the fluid is depleted the brakes will not operate likely causing catastrophic danger to life and property. Brake assembly components are often referred to as foundation components because they are the primary sections the rest of the system is built on. Foundation components are the mechanical parts in and around the wheels which operate the air brakes.

Why Air Brakes are Used on Commercial Vehicles

Foundation brakes are the most common air brake systems in trucks and buses. They use a triple-valve principle which charges air into the tank, applying the brakes, and releasing them. Pressure increases in the cylinder while applying the brakes and in turn decreases pressure in the reservoir. The majority of the vehicles with air brakes have a graduated release system which allows a partial increase in pressure that delivers a proportional release in the brakes.

The components listed below make up a foundation air brake system in trucks and buses:

• Air compressor: Pumps the air into storage tanks

• Air compressor governor: Maintains a set amount of air in the tanks that is coming from the compressor

• Reservoir tanks: Holds the pressurized air

• Drain Valves: Release valves that drain air from the tanks that is coming from the compressor

• Brake pedal: Essentially a valve that when it is depressed, air is released from the reservoir tanks

• Brake chambers: A tube-shaped vessel which contains a slack adjuster that moves a cam or

diaphragm device

• Push rod: A steel rod that attaches the brake chamber to the slack adjuster. When extended, the brakes are

applied; if depressed, the brakes release

• Slack adjusters: An arm which attaches the push rod to the brake s-cam for regulating the distance between

the brake shoes

• Brake S-Cam: An S-shaped cam that is a rotating or sliding piece in the mechanical linkage used to transform

rotary motion into linear motion that pushes the brake shoes apart and presses against the brake drum

• Brake shoe: The part of a braking system which carries the brake lining that creates friction against the

brake drum

• Return spring: A small, rigid spring that is linked to each brake shoe which returns the shoe back to the open

position when not depressed.

• Push-to-Connect Fittings: D.O.T. fittings that connect air lines

When the brakes are not depressed and the vehicle’s air system is charged, the air pressure keeps the s-cam or diaphragm in the closed position releasing pressure from the brake system. When the brake pedal is pushed down the air pressure is reduced which then turns the s-cam and spreads the brake shoes causing friction against the drum. The compressor then refills the reservoir tanks. When the pedal is allowed to retract, the air pressure increases back to its initial state.

Emergency air brakes, or parking brakes, are a necessary counterpart to the air brake system which is activated by pulling a square yellow button on the dash. The button is pulled out when the vehicle is parked, especially on an incline. Before driving the vehicle, the emergency brake button must be pushed in to release the emergency brake and fill the system with air. The emergency brake will remain free if the emergency system is pressurized. If there is a leak in the system the pressure can decrease which can engage the emergency brake. Heavy trucks often have an exhaust brake that assists the braking process, yet is dependent on the engine, not the air brake system.

D.O.T. Air Brake Fittings

Another extremely important set of components to an air brake system are the fittings that connect the air lines. These fittings must be Department of Transportation compliant and are referred to as

D.O.T. fittings.

D.O.T. fittings are designated and approved by the Department of Transportation for commercial motor vehicles. The D.O.T. approves both push-to-connect

and compression fittings. The requirements for D.O.T.

air brake fittings follow Title 49 of the Code of Federal Regulations, Section 571.106. Most sources agree that the benefits of push-to-connect fittings far outweigh those of compression fittings in air brake applications:

• Push-to-connect fittings are more compact and installed and disassembled on the hose by hand, which makes it faster and easier in confined areas. Compression fittings, however, require tools to install and disassemble.

• D.O.T. push-to-connect air brake fittings provide a leak free seal by properly pushing the tube or hose into the fitting. On the other hand, the nut on a compression fitting must be torqued to a specific rating to ensure a proper seal.

• It is very uncommon to have to adjust a push-to-connect fitting, however, a compression fitting can become loose due to frequent vibration and needs to be retightened to prevent a leak. Doing so can cut into the tube or cause crimping, which can increase the opportunity for leaks even more.

• The reduction in assembly time of push-to-connect fittings versus compression style can be up to 90%. Putting this into perspective, a mechanic could assemble as many as 900 push-to-connect fittings in one hour, versus 90 compression style fittings in the same amount of time.

It is important to note that though D.O.T. push-to-connect fittings are approved for all primary air brake applications, they are not designed for use between the frame and axle or between vehicles in tow.

Different Materials

There are two types of push-to-connect fitting materials commonly used: composite and brass.

COMPOSITE

The development of composite body push-to-connect fittings has provided a significant advancement over their brass counterpart. Though brass is still a common material, the polymer body and brass screw threads in a composite fitting are extremely durable and provide labor-savings, lighter weight and lower cost compared to brass push-to-connect fittings.

Typically composite push-to-connect fittings are approximately 43% lighter than the same brass fitting size. Considering there are about 60 to 100 D.O.T. fittings used on a tractor-trailer the weight savings is around 7 to 9 pounds per vehicle. This may not seem like much for one truck, yet it adds up when dealing with a large fleet. Especially considering that even the smallest reduction in weight can provide significant fuel efficiency and payload potential across an entire the fleet.

BRASS

Brass body D.O.T push-to-connect fittings are a major improvement over the use of the legacy brass compression fitting. Like a composite body fitting, they reduce installation time and complexity, and still meet or exceed the performance of brass compression fittings. The internal collet and O-ring seal provides a comparatively leak-free assembly without the need for additional tools. And brass fittings do not corrode, rust or become brittle in cold temperatures. Like composite fittings, brass push-to-connect fittings are also quick and easy to assemble, reducing labor costs.

Different Styles & Configurations

The styles and configurations of push-to-connect fittings are typical to the configuration of compression fittings, which include:

• Bulkhead Fittings

• Elbow Fittings

• Straight Fittings

• Tee Fittings

• Tube to NPT Fittings

• Union Fittings

• Y Fittings

Most of the above are available with push-to-connect at one or more ports and male or female NPT end connections the other port(s).

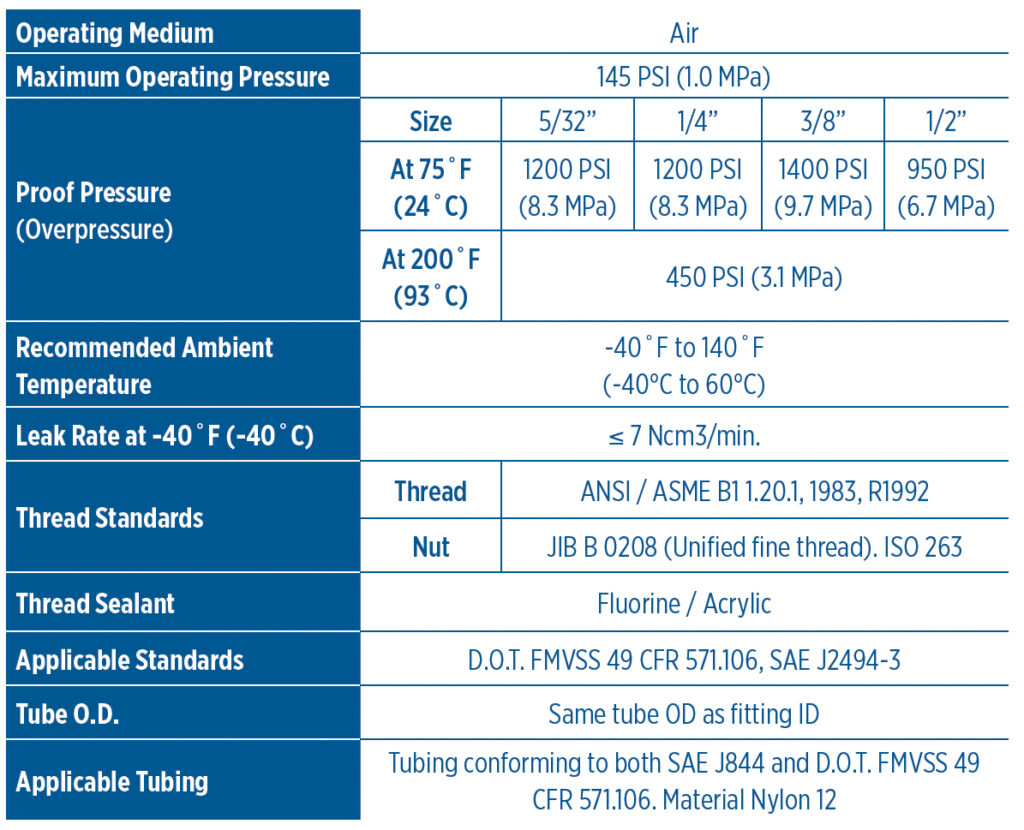

Specifications for D.O.T. and SAE Compliant Fittings

Conclusion

Our roads and highways are becoming busier each day, with more and more commercial vehicles on the road requiring an increasing need for solutions to help drivers respond to a variety of conditions. Federal safety requirements are set forth by the Federal Motor Carrier Safety Administration’s Compliance, Safety &

Accountability standards.

According to a Department of Transportation study 29 percent of all large truck accidents in the United States involve brake failures. In addition, roughly 11% of all traffic accident fatalities in the U.S. are caused by semi trucks. In 2017, 97% of traffic deaths involving one semi truck and one passenger vehicle were those in the passenger vehicle. There are a number of factors which make semi truck accidents particularly dangerous. One fully loaded tractor trailer can weigh as much as 40 tons, while the typical passenger vehicle is approximately 2.5 tons. And a semi can take 20 to 40 percent farther to stop than a car. This difference is greater on wet and slippery roads or with poorly maintained brakes.

Each state has its own guidelines that are specific to operating a vehicle with air brakes. To become a commercial driver there is extensive training and testing to obtain a license. In the same respect, there are required steps to manufacture and maintain a vehicle to ensure components meet D.O.T specifications. To help ensure safety on the road, there are some basic steps that should be taken with a truck or buses’ air brakes at routine intervals throughout a short or long haul:

1. Maintain a minimum operating pressure of the air brake system at no less than 100 PSI for a truck and 85 PSI for a bus

2. Make sure the air pressure buildup rate is two minutes or less to rise to the specified PSI.

3. Do not depend on the sound of the air pressure discharging. The air compressor governor should cut out before pressure reaches 140 PSI

4. Avoid water in the air brake system, which is caused by condensed air. In colder temperatures, ice can block air from reaching the brakes, causing the wheels to lock-up. Most newer braking systems have automatic drain valves installed in each air tank to prevent this from happening.

Trucks and even buses must keep a tight schedule in their route and safety checks and maintenance on the road cuts into drive time. Considering that the braking system is critical for safe operation on the vehicle, regular inspections of the air lines is extremely important. If fittings need to be adjusted or replaced D.O.T push-to-connects are the fastest and easiest compared to compression fittings. They also provide a safer and more reliable connection, reducing the chance of loosening or over tightening which can increase the possibility of air leaks. Using D.O.T. push-to-connect fittings for adhering to today’s standards for slowing and stopping a commercial truck or bus are imperative for the safety of our roadways.

SOURCES:

Bendix

Fleet Equipment Magazine

Fleet Owner

InfoSpace Holdings

KNILT

Nurenberg – Paris

Ontario Ministry of Transportation

TGA Truck Driving School